This technology is commercially available

We are proud to announce that our glass process technology is now being commercialized by our spin-off Glassomer GmbH.

Why glass?

Glass is a fascinating material and has many advantages like its outstanding optical transparency, thermal and chemical resistance and well known surface properties. Rapid prototyping and microstructuring has however been difficult and time consuming as structuring is commonly done using wet chemical etching techniques which require hazardous hydrofluoric acid.

What is "Liquid Glass"?

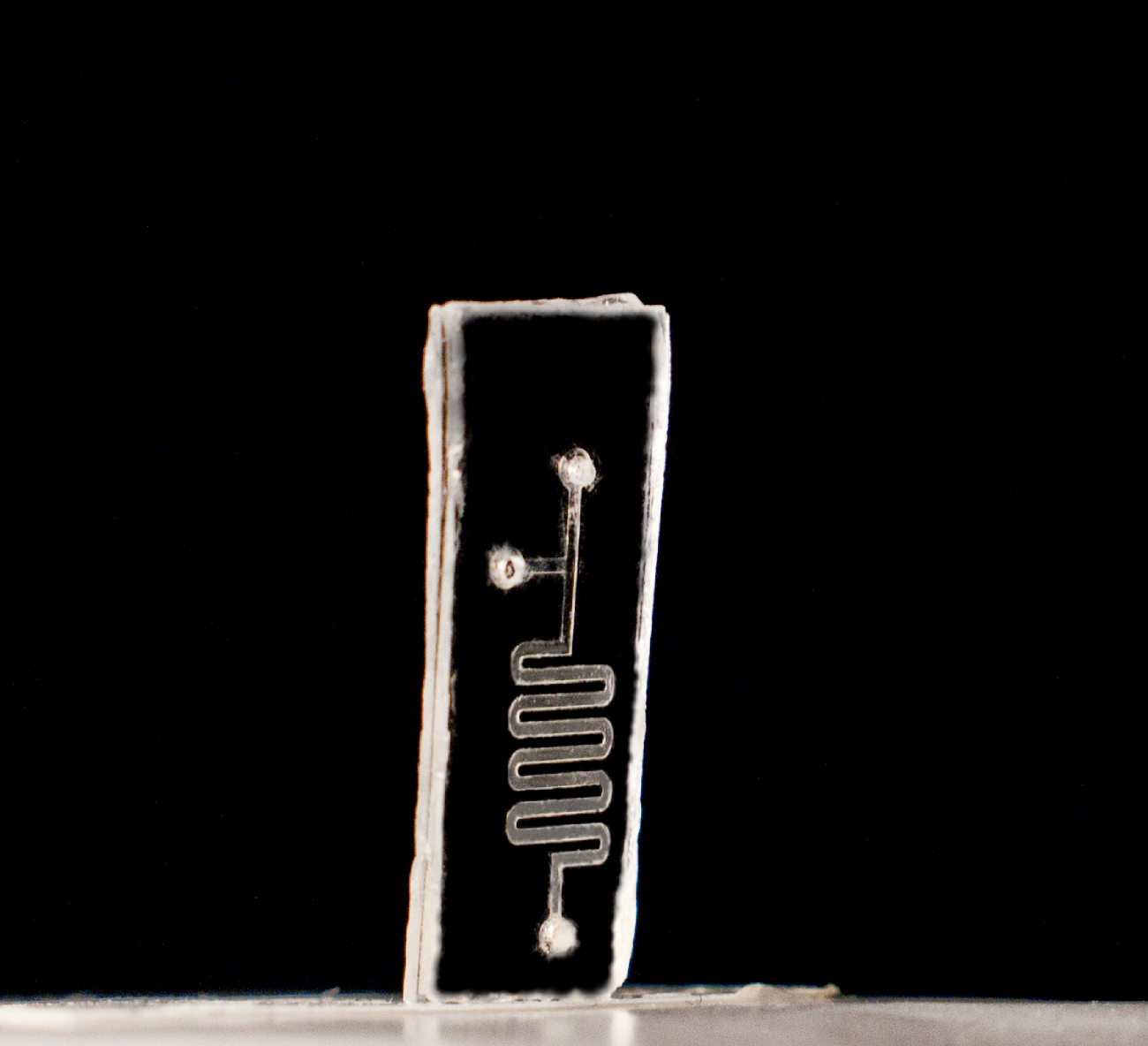

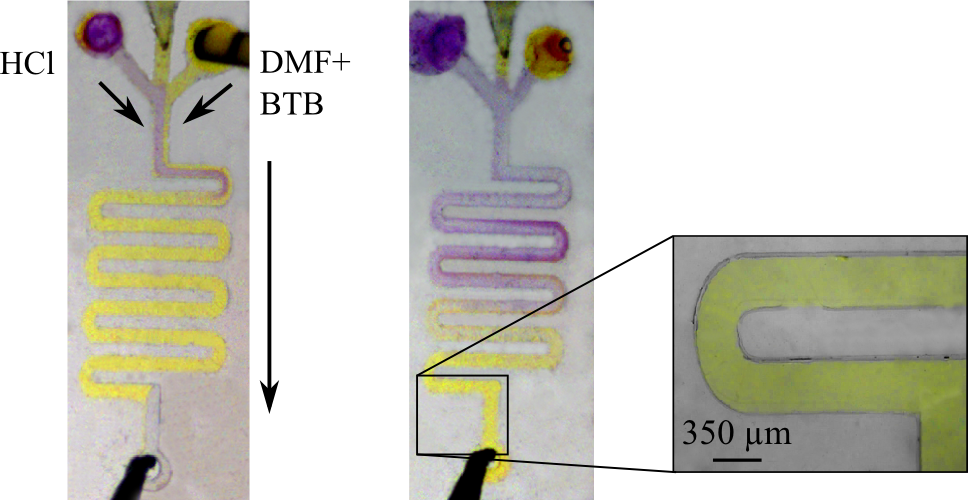

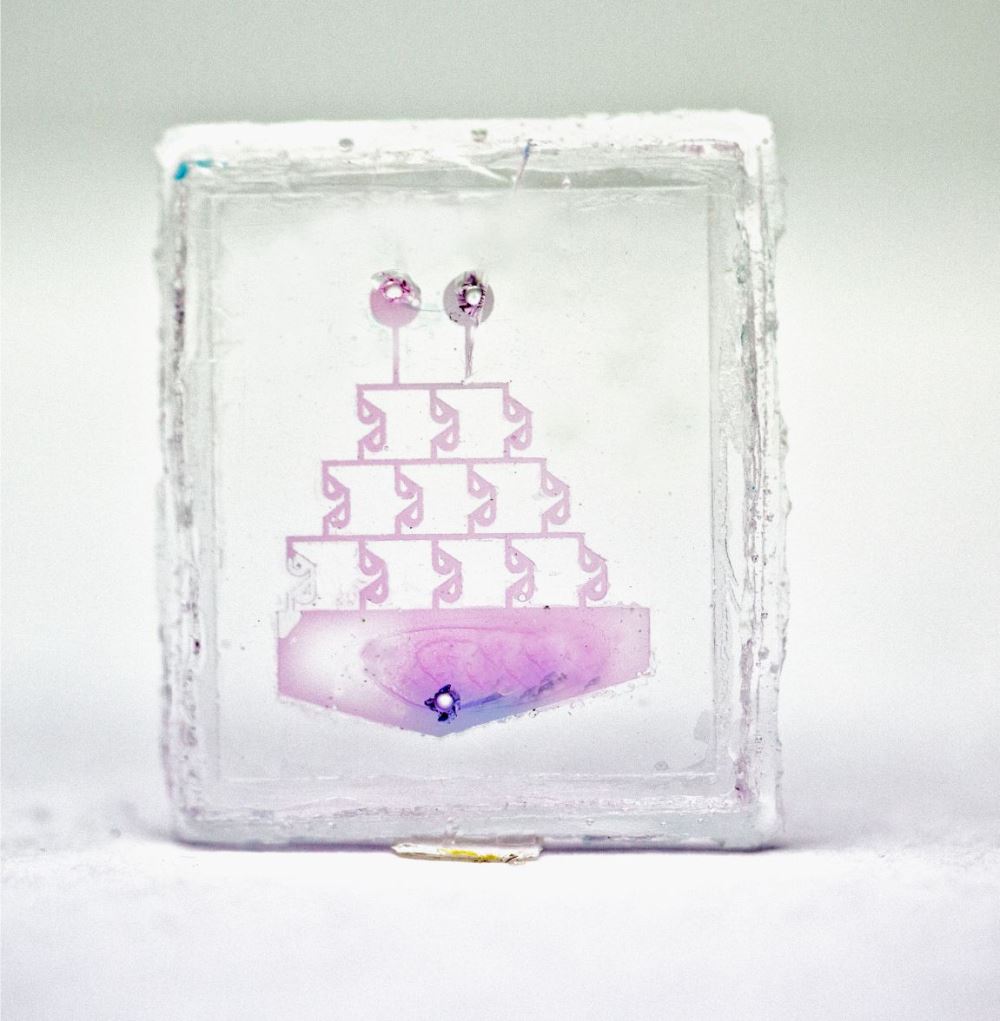

"Liquid Glass" is a nanocomposite containing amorphous silica, which can be structured using by room-temperature replication using soft molds. The solid polymer-composite component is subsequently thermally debound and sintered to a high-quality transparent glass. The resulting glass is chemically and physically identical to commercial fused silica glass. Using “Liquid Glass” it is possible to convert arbitrary physical objects in almost any material into glass rapidly and conveniently with feature sizes in the range of tens of micrometers and surface roughness in the range of a few nanometers. Lamination of cured “Liquid Glass” allows the creation of complex physical structures with e.g. closed cavities or microfluidic channels.

3D printing of transparent fused silica glass | Paper | Media Coverage

In April of 2017 we published our very first paper in Nature.

See our video for more details on this technology.

Glassomer - Processing glass as if it was a polymer | Paper

In our recent paper in Advanced Materials we introduce a novel processing technique for glass termed Glassomer. Now glass can be machined as if it was a polymer. Always wanted to carve glass by hand? Now you can!

Associated Publications

Journal Papers

M. Mader, O. Schlatter, B. Heck, A. Warmbold, A. Dorn, H. Zappe, P. Risch, D. Helmer, F. Kotz, B. E. Rapp: “High-throughput injection molding of transparent fused silica glass”, Science, 2021 | Link

M. Langenhorst, D. Ritzer, F. Kotz, P. Risch, S. Dottermusch, A. Roslizar, R. Schmager, B. S. Richards, B. E. Rapp, U. W. Paetzold: "Liquid Glass for photovoltaics: multi-functional front cover glass for solar modules", ACS Materials & Interfaces, 2019 | Link

F. Kotz, P. Risch, K. Arnold, S. Sevim, J. Puigmarti-Luis, A. Quick, M. Thiel, A. Hrynevich, P. Dalton, D. Helmer, B. E. Rapp: “Fabrication of arbitrary three-dimensional suspended hollow microstructures in transparent fused silica glass”, Nature Communication, 10, 1439, 2019 | Link

|

|

F. Kotz, K. Arnold, W. Bauer, D. Schild, N. Keller, K. Sachsenheimer, T. M. Nargang, C. Richter, D. Helmer, B. E. Rapp: "Three-dimensional Printing of Transparent Fused Silica Glass", Nature, 544, 337-339, 2017 | Link | Video | Media Coverage

F. Kotz, K. Plewa, W. Bauer, N. Schneider, N. Keller, T. Nargang, D. Helmer, K. Sachsenheimer, M. Schäfer, M. Worgull, C. Greiner, C. Richter, B. E. Rapp: “Liquid Glass: A Facile Soft Replication Method for Structuring Glass”, Advanced Materials, 28, 4646-4650, 2016 Media Coverage | Link

Reviews

F. Kotz, P. Risch, D. Helmer, B. E. Rapp: “High-performance materials for 3D printing in chemical synthesis applications”, Advanced Materials (invited), 2019 |Link|

Books and Book chapters

F. Kotz: “Entwicklung neuer Materialien für die additive Fertigung und das Rapid Prototyping von Glas und Polymethylmethacrylat”, KIT Scientific Publishing, Karlsruhe, ISBN 978-3-7315-0835-9, 2018 | Link

Conference Contributions

F. Kotz, P. Risch, M. Thiel, A. Quick, D. Helmer, B. E. Rapp: “Sacrificial Template Replication: Fabrication of arbitrary 3D microfluidic channels in transparent fused silica glass”, talk, SPIE Photonics West, San Francisco, USA, 2020

F. Kotz, L. Kneißl, P. Risch, B. E. Rapp: “Rapid prototyping of alumina-based microfluidic reactors”, talk, SPIE Photonics West, San Francisco, USA, 2020

“Facile integration of electronics in glass microfluidic devices for electrochemical synthesis and analysis”, talk, SPIE Photonics West, San Francisco, USA, 2020

M. Langenhorst, D. Ritzer, F. Kotz, P. Risch, I. Hossain, S. Dottermusch, A. Roslizar, R. Schmager, B. S: Richards, B. E. Rapp, U. W. Paetzold: „Advanced optical microstructures embedded in transparent encapsulation glass for photovoltaics”, talk, SPIE Photonics West, San Francisco, 2019.

F. Kotz, A. Striegel, N. Schneider, M. Worgull, D. Helmer, B. E. Rapp: „High-throughput structuring of fused silica glass“; talk, MNE, Kopenhagen, 2018.

P. Risch, F. Kotz, D. Helmer, B. E. Rapp: "3D printing of microfluidic glass reactors", poster, 22nd International Conference on Miniaturized Systems for Chemistry and Life Sciences (µTAS), Kaohsiung, Taiwan, 2018.

F. Kotz, A. Striegel, N. Schneider, P. Risch, M. Worgull, D. Helmer, B. E. Rapp: "High-throughput polymer molding of transparent fused silica microfluidic chips", poster, 22nd International Conference on Miniaturized Systems for Chemistry and Life Sciences (µTAS), Kaohsiung, Taiwan, 2018.

F. Kotz, P. Risch, K. Arnold, D. Helmer, B. E. Rapp: “Next generation 3D printing - The emergence of enabling materials”, talk, SPIE Defence and Security, Berlin, Germany, 2018| Link

B. E. Rapp: "Next Generation 3D Printing - The emergence of enabling materials", talk, Microfluidics in the Upper Rhine Valley, IS2M Mulhouse 2018.

F. Kotz, K. Arnold, B. E. Rapp: "Three-dimensional Printing of Transparent Fused Silica Microfluidic Chips", talk, 21st International Conference on Miniaturized Systems for Chemistry and Life Sciences (µTAS), Savannah, USA, 2017

F. Kotz, K. Arnold, B. E. Rapp: “Rapid manufacturing of microfluidic chips in glass”, poster, 20th International Conference on Miniaturized Systems for Chemistry and Life Sciences (µTAS), Dublin, Ireland, 2016

F. Kotz, K. Plewa, C. Richter, B. E. Rapp: “Rapid prototyping of microfluidic chips in glass using a soft-lithography-compatible manufacturing process”, poster, 19th International Conference on Miniaturized Systems for Chemistry and Life Sciences (µTAS), Gyeongju, Korea, 2015

F. Kotz, K. Plewa, W. Bauer, T. Hanemann, A. Waldbaur, E. Wilhelm, C. Neumann, B. E. Rapp: “Rapid prototyping of glass microfluidic chips”, talk, SPIE Photonics West, San Francisco, USA, 2015| Link

F. Kotz, C. Richter, B. E. Rapp: “A new rapid prototyping method for the fabrication of microfluidic chips in glass”, poster, Gordon Research Conference, Mount Snow, USA, 2015

Patents

B. E. Rapp, F. Kotz: "Transparentes Quarzglas für die additive Fertigung", DE102016012003, 2016 | Link.

B. E. Rapp, F. Kotz: "Composition and process for producing a molded article of high-purity, transparent quartz glass by means of additive manufacturing”, WO2018065093, 2016 | Link.

Miscellaneous

D. Helmer, B. E. Rapp: "Healthcare Material Platforms", HEALTH 2, Paneuropean Network, 2017. The NeptunLab is features on the cover page of the issue | Link | Cover

F. Kotz, N. Schneider, A. Striegel, A. Wolfschläger, N. Keller, M. Worgull, W. Bauer, D. Schild, M. Milich, C. Greiner, D. Helmer, B. E. Rapp: “Glassomer: Processing Fused Silica Glass like a Polymer”, Advanced Materials, 30, 1707100, 2018

F. Kotz, N. Schneider, A. Striegel, A. Wolfschläger, N. Keller, M. Worgull, W. Bauer, D. Schild, M. Milich, C. Greiner, D. Helmer, B. E. Rapp: “Glassomer: Processing Fused Silica Glass like a Polymer”, Advanced Materials, 30, 1707100, 2018